Automated Material Handling

In automated processes, all parameters must fall into the right place for production to run optimally. Packaging play a crucial role in that story. Standard packaging is often sufficient to ensure that everything runs smoothly, but in certain cases customization is also required.

Eurotec bins

Our Eurotec series is specially designed for handling in automatic warehouses. Learning from dozens of projects (such as Festo, Omron, Tele Denmark, Road Air, Brezan) we have added multiple enhancements to the standard Eurotec bin. Eurotec bins are often used for internal handling and supplied specifically for a project.

Eurotec containers are available with different types of bottoms. Because the shape and load capacity of the bottom determine the usability in an automatic warehouse. Closed handles are standard, because manual handling is the exception.

Eurotec containers always have two label holders, one on the long side and one on the short side. No matter how they are placed on pallets, the contents are always recognisable.

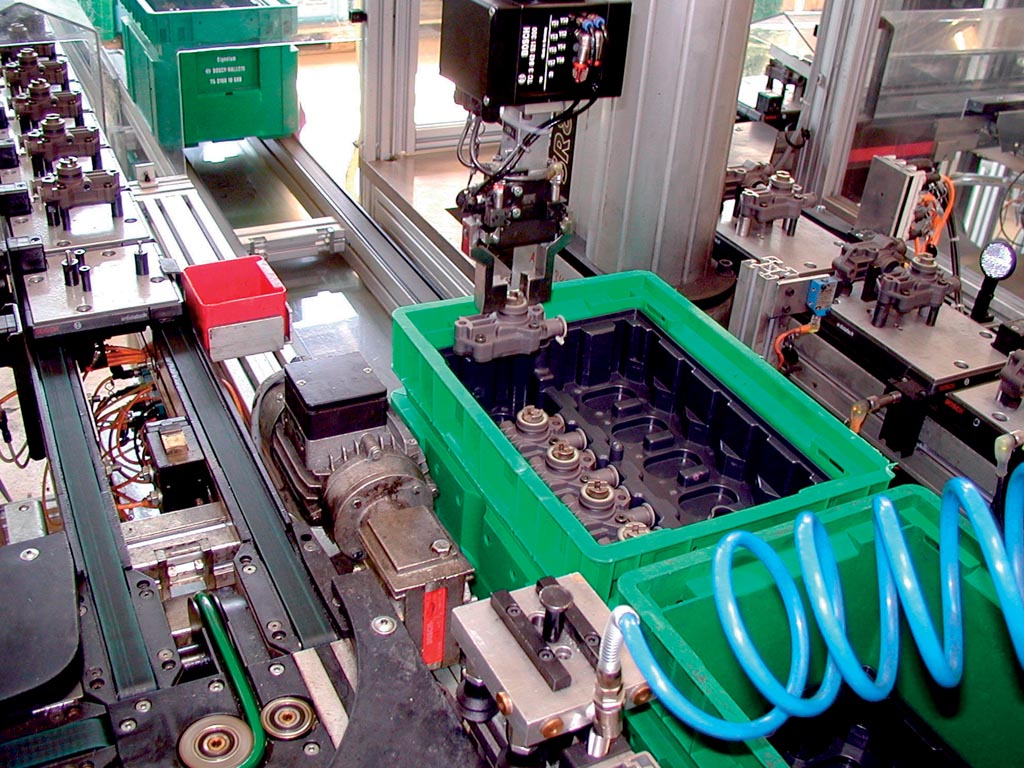

Everywhere there are points of application for positioning and recording by robots and auxiliary equipment. Applying labels, barcode label frames and transponders is standard for us; locations and holders are provided.

Product carriers/transport trays

In automated production processes, it is often crucial that semi-finished products are presented to a robot in an oriented manner or that certain areas of the product do not come into contact with the packaging. We can completely customize the product carrier to these requirements.

Vacuum-formed trays

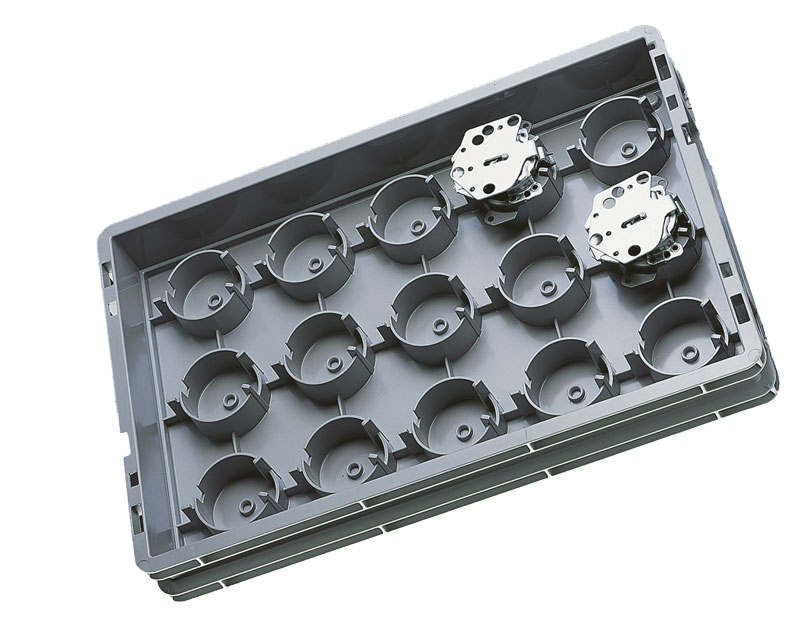

If we look at the classic solution, we often see a plastic transport container with vacuum-formed interiors or trays as a product carrier. The container ensures stackability and manageability, the interior positions and protects the parts to be transported. The interiors are removable and can be stored efficiently, so that the plastic container can be used for storage or forwarding to the next link in the chain.

Current vacuum-form techniques can produce the container and the interior in one go. This is relatively cheaper, because one package does not have to be produced twice. That is why we invest in vacuum molds with spare parts that combine both functions: stackable trays.

Injection-formed trays

It is also possible to create product carriers by means of injection moulding. Injection molded trays are the solution, especially when a higher load capacity is required. Here, too, Engels has various interchangeable mold parts for bottoms and side walls so that adjustments can easily be made according to the needs of your product.

Developed with our customers

One third of the packaging supplied by us consists of customized plastic containers or plastic trays designed, produced and assembled on behalf of the customer. It often concerns an adjustment or addition to a standard product from our range, or completely new products are developed.

When dealing with packaging issues we always sit around the table with the customer. We start with an inventory of his needs (how does the product arrive, how is it processed and stored internally, what are the critical parts of the product, etc.) and see how we can respond to them. Minor adjustments to standard products are often sufficient to provide the right solution. If not, we'll start from scratch.

Interiors are an important part of packaging

Interiors not only protect, they standardize, organize and position the high-end products of the manufacturing industry.