Flight cases

product(s)

Color dark-grey

Weight 5 kg

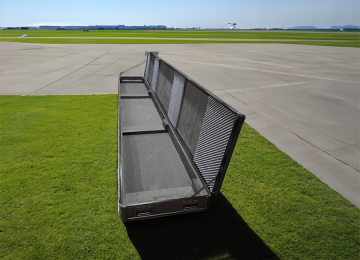

Dimensions L:3000 x W:800 x H:600

Color dark-grey

Weight 30 kg

Dimensions L:600 x W:400 x H:350

Color dark-grey

Weight 5 kg

Dimensions L:400 x W:300 x H:225

Color dark-grey

Weight 2 kg

Protective transport packaging is essential for transporting professional and expensive equipment. For example, flight cases have been self-evident for years for the safe transport of microphones, mixing panels, cables, etc. The disadvantage of standard flight cases is the weight of the wooden plates used (usually birch). This means that the heavy flight case usually has to be moved by several people or by special equipment.

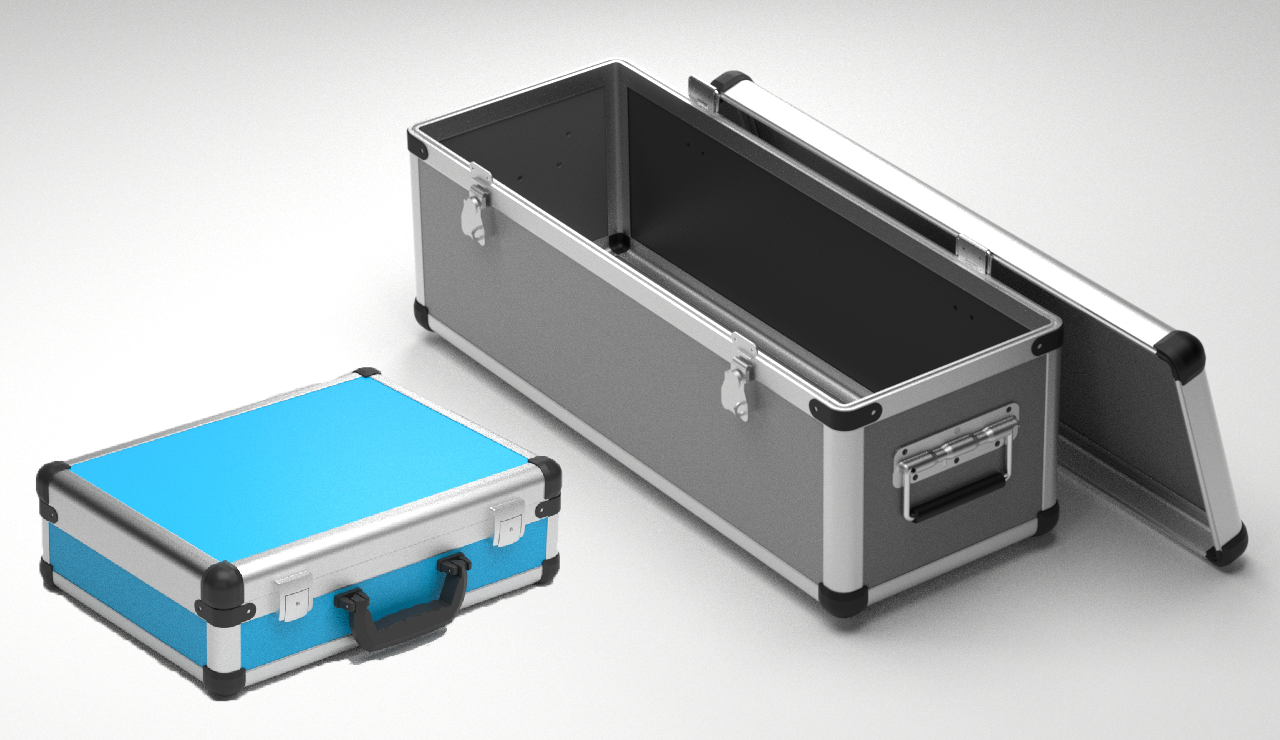

Traditional flight cases are made with a laminated plywood panels that are riveted to the extrusion. While this is strong, we decided to use lightweight open core panels that are bonded to the extrusions allowing us to make the cases with a much cleaner appearance, lighter weight and using far fewer rivets in the construction which gives us a build time advantage over plywood flight cases.

We finish our flight cases by using either anodising or powder coating on our flight case extrusions making them more durable than traditional mill finish extrusions that are used by most other flight case manufacturers.

Most other flight case manufacturers use either a plain aluminium angle extrusion, this has an outer and inner section, this increases the strength over a plain angle but is nowhere near as strong as our exclusive box section extrusions that we use.

Flight Case Features

With our Digital UV print facilities and a full range of panel colours and machined interior foam options available we are sure that our flight cases stand alone in terms of strength, durability and design.